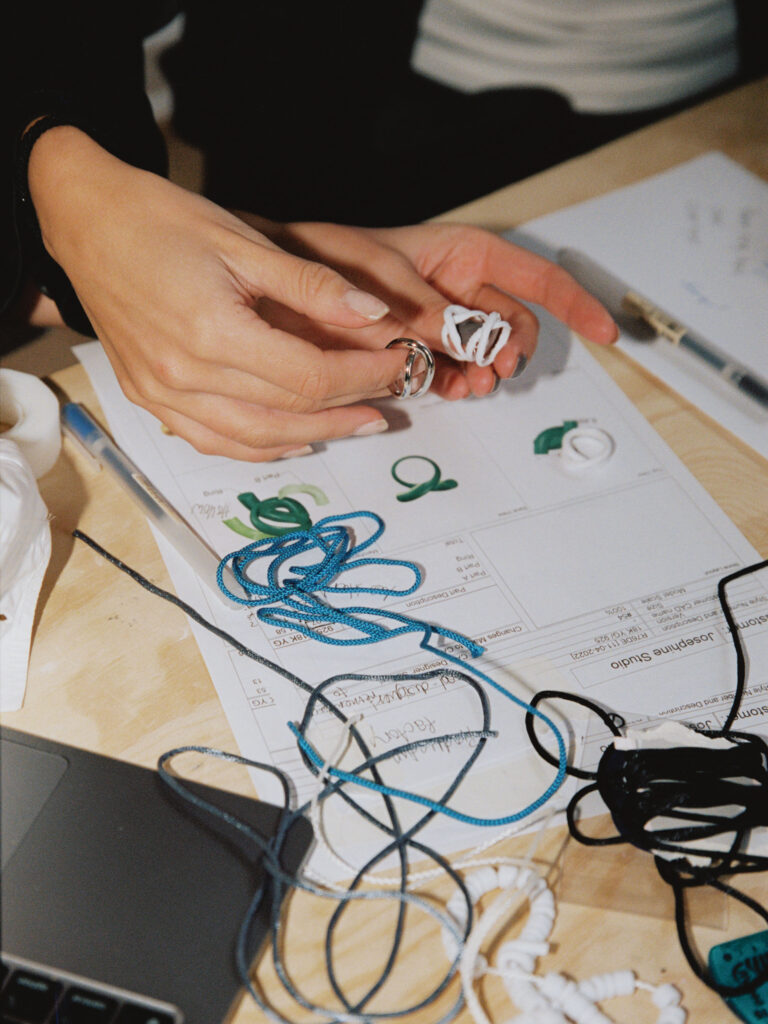

Oslo-based contemporary fine jewellery label Josephine uses solid materials — sterling silver and solid gold, avoiding any form of gold plating. The brand, Sarah Herland says, also emphasises comfort as a cornerstone of its design philosophy. Together with her co-founder, Camilla Johnsen (pictured left above, next to Sarah), she also works extensively with 3D printing as a part of the design process.

— We 3D print all our designs to quickly get an understanding of dimensions, proportions, and feel. As comfort is paramount, this allows us to test and refine the design until it feels perfect on the body before proceeding to production, she shares, continuing,

— I was introduced to 3D printing during my Master’s degree in Industrial Design at the Oslo School of Architecture and Design. I’ve never been particularly good at drawing, but I have always had a relatively technical inclination. So, when I discovered that I could bring all my ideas to life in 3D, it quickly became a field in which I specialised deeply. Since then, 3D has become my pencil, enabling me to sketch out all my thoughts and print them in 3D.

What are the benefits of using it?

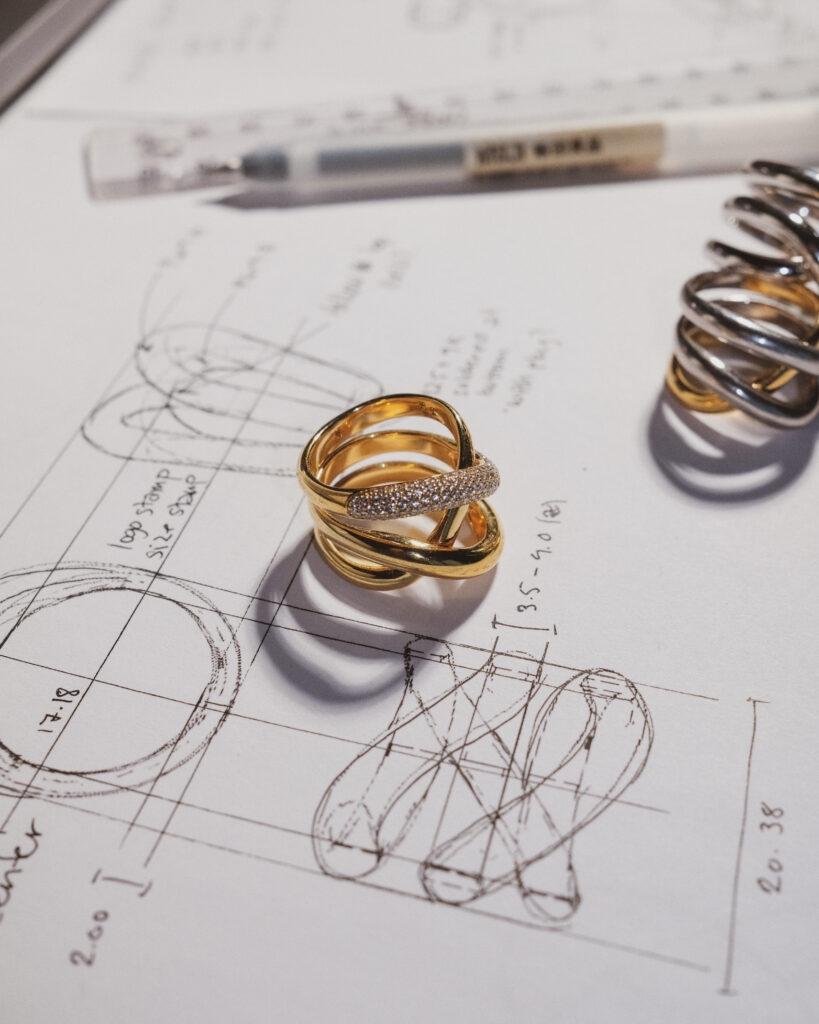

— The integration of 3D printing in jewellery production has revolutionised traditional crafting methods, offering huge advantages in both design precision and environmental sustainability. This technology allows for the creation of precise and intricate designs that were once challenging to achieve manually, speeding up the design process and conserving resources.

— A key benefit lies in the ability to produce models in a 1:1 scale, providing an accurate representation of the final product. This enhances the creative process and enables complete control over the design before full-scale production. The flexibility of 3D printing empowers us to explore innovative concepts, bringing intricate details and unique shapes to life.

— Moreover, the cost-effectiveness of 3D printing in the jewellery industry is noteworthy. Rapid prototyping and design testing enable swift calculation of production costs based on the 3D model, allowing adjustments to align with budget constraints without compromising quality. This streamlined approach ensures the end product meets both aesthetic and financial expectations.

— The transformative advantages of incorporating 3D printing into jewellery production extend to environmental benefits. The technology minimises material waste by allowing precise usage, promoting a more sustainable manufacturing process. The reduced need for physical samples in design testing further diminishes resource consumption and contributes to a lower overall environmental footprint.

— Additionally, the efficiency of 3D printing in jewellery production translates to energy savings, aligning with the global push towards energy-efficient and eco-friendly practices. It not only redefines design possibilities in jewellery crafting but also stands as a positive force in the pursuit of sustainable and responsible manufacturing, minimising waste, reducing resource consumption, and promoting energy efficiency.

Previous drawbacks, Herland shares, often revolved around print quality and accuracy. With new machines though, that’s no longer a problem.

— For those printing very large objects, 3D printing can be time-consuming and expensive, but for jewellery, we can have a finished ring in 10-30 minutes. Our only current challenge is that the printer is quite big! We don’t have an office yet, so the 3D printer sits in the middle of my living room in my studio apartment…

— We extensively utilise 3D printing. When we launched our website last year we conducted a pre-sale based on 3D renderings. Our first line sheets and initial retail deals were also made based on only 3D renderings. Additionally, we use 3D to design window displays in retail stores carrying our brand, as well as to develop shop-in-shops and showrooms. 3D is our primary tool.

The last few years have seen strong growth for Norwegian jewellery brands. This is also driven by the special Jewellery Exhibition at the national fashion week, Oslo Runway, which is arranged every August — and where Josephine was a part of a strong lineup last year. The question is: Why? And why now?

— It’s somewhat peculiar that we’re seeing so many Norwegian jewellery brands these days, especially when you consider that we are a small country. I generally believe that Norway has a rich artistic and creative environment, which may have contributed to the emergence of talented jewellery designers who wish to express their artistic vision through jewellery production. We also recognise the advantage of Norway being a small country when it comes to building a brand, both because the fashion and design industry in relatively small compared to other countries and because we strongly feel the support from Norwegians in general. Norwegians support each other! Herland concludes.